Product Consultation

Your email address will not be published. Required fields are marked *

Mid-Certification Standards Unpacked: A Deep Dive into EN50470-1/3 vs. EN50470-3:2022 and Their Impact on Smart Metering

Mar 28,2025

How Do Power Analyzers Drive Efficiency and Innovation in Modern Energy Systems?

Mar 24,2025

What are the pros and cons of using current sensors versus traditional fuses or circuit breakers for overload protection?

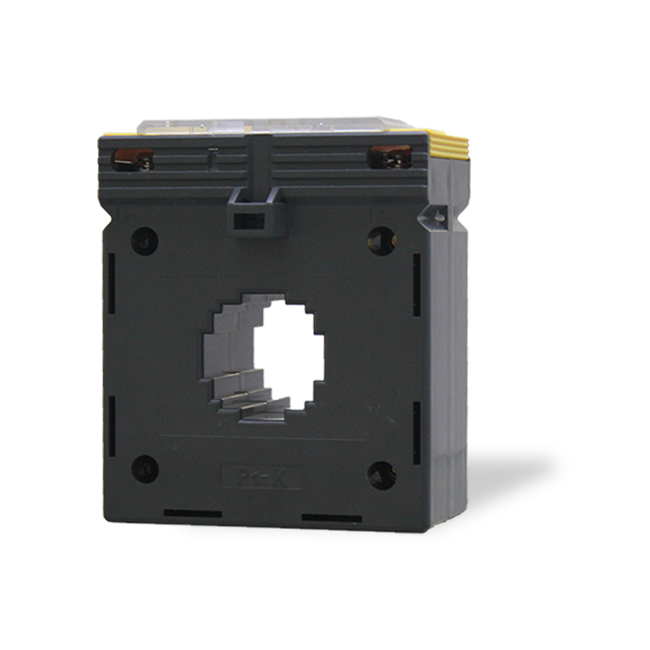

Mar 21,2025Solid core current sensors are particularly well-suited for several applications due to their design and performance characteristics.

1. Industrial Automation

In industrial settings, solid core current sensors play a vital role in monitoring motors, pumps, and various electrical loads. They provide real-time data on current consumption, which is essential for controlling processes and ensuring equipment operates within safe limits. For instance, if a motor begins to draw excessive current, the sensor can trigger alarms or shut down the system to prevent damage. The ability to monitor load variations helps in optimizing energy usage and enhancing system reliability.

2. Energy Management Systems

Solid core current sensors are integral to energy management systems in both commercial and residential buildings. They allow for precise tracking of electrical consumption, enabling facility managers and homeowners to identify usage patterns and inefficiencies. By integrating these sensors into smart grid technologies, users can implement demand response strategies, shifting usage to off-peak hours, thus reducing energy costs. Their accurate readings are also crucial for calculating overall power factor and improving energy efficiency.

3. Renewable Energy Systems

In solar power installations, solid core current sensors monitor the output of solar inverters, providing essential feedback on system performance. By measuring the current generated by solar panels, these sensors help ensure that the energy produced is effectively utilized or stored. This data can be crucial for maintenance, as any deviations from expected current levels may indicate issues with panel performance or inverter functionality.

4. Power Distribution

Solid core current sensors are widely used in power distribution networks to monitor current flow through transformers, switchgear, and circuit breakers. This monitoring is essential for maintaining grid stability and efficiency. By providing real-time insights into load conditions, these sensors help utilities manage supply and demand effectively, preventing overloads and facilitating timely maintenance interventions.

5. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, solid core current sensors are employed to monitor the performance of compressors, fans, and pumps. By tracking the current draw of these components, facility managers can detect operational anomalies such as motor failure or mechanical blockages. This proactive monitoring not only enhances energy efficiency but also prolongs equipment life by preventing overheating and associated damage.

6. Motor Protection

Solid core current sensors are critical in motor protection applications. They provide essential data for monitoring operating conditions, helping to detect issues like overloads, stalls, and phase imbalances. When the sensor identifies an abnormal current draw, it can activate protective measures such as circuit breakers or alarms, preventing costly damage and unplanned downtime.

7. Data Centers

In data centers, solid core current sensors are utilized to monitor the power usage of various servers and equipment racks. This monitoring is crucial for ensuring efficient load distribution and managing energy consumption across the facility. By providing insights into current draw, operators can implement load balancing strategies, optimize cooling requirements, and identify underutilized resources, ultimately enhancing operational efficiency.

Reasons for Suitability

Accuracy: Solid core current sensors deliver precise current measurements, which are critical in applications where monitoring and control are essential for safety and efficiency.

Safety: Their design allows for electrical isolation between the high-voltage circuit and the measuring instrument, enhancing safety in high-voltage environments.

Durability: Solid core sensors are robust and can withstand harsh industrial conditions, including temperature fluctuations, vibrations, and exposure to dust or moisture, making them reliable for long-term use.

Simplicity of Installation: They are relatively easy to install and integrate into existing systems without significant modifications, making them a convenient choice for upgrades or new installations.

Cost-Effectiveness: Given their longevity and low maintenance requirements, solid core current sensors can be a cost-effective solution for many applications.

Solid core current sensors are well-suited for a variety of applications due to their accuracy, safety features, durability, and ease of use. Their ability to provide reliable current measurements makes them invaluable tools for enhancing efficiency and protecting electrical systems across numerous industries.

Your email address will not be published. Required fields are marked *

We develop and produce high performance electricity meters, power analyzers, current sensors, communication modules and management systems. China Custom Smart Meters Manufacturers and Factory

Address: NO 52, Dongjin Road, Nanhu, Jiaxing, Zhejiang, China

Copyright @ Eastron Electronic Co., Ltd. All rights reserved Electricity Meters Manufacturers